At present, elevator technology is changing rapidly, and the continuous emergence of high safety and high-performance elevator products not only improves people’s quality of life, but also creates more economic benefits for social production. However, some elevators that have been in use for a long time and have a low quality level, due to their high failure rate, poor comfort, low safety and reliability, can no longer meet the needs of modern social development, and have become problems that we face solving. In order to extend the service life of elevators, ensure their safety and operational quality, people will carry out a series of services such as maintenance, repair, and renovation after the elevators are put into use. There is a certain reason why some major elevator companies claim that their manufactured elevators will coexist with buildings. We believe that achieving this goal should be closely related to its subsequent maintenance, repair, and renovation services.

The renovation of elevators in use is not carried out for no reason, but has a certain necessity. These are closely related to factors such as the aging of components, outdated technology, and inadequate functionality of elevators in use.

As is well known, elevators are highly dangerous special equipment. In order to ensure the safe operation of elevators and protect the safety of people’s lives and property, the state implements a licensing system for elevator production. The quality and technical supervision bureau implements a safety supervision system for elevator management, which means that in addition to inspecting newly installed elevators, annual safety inspections are carried out on in-service elevators once a year.

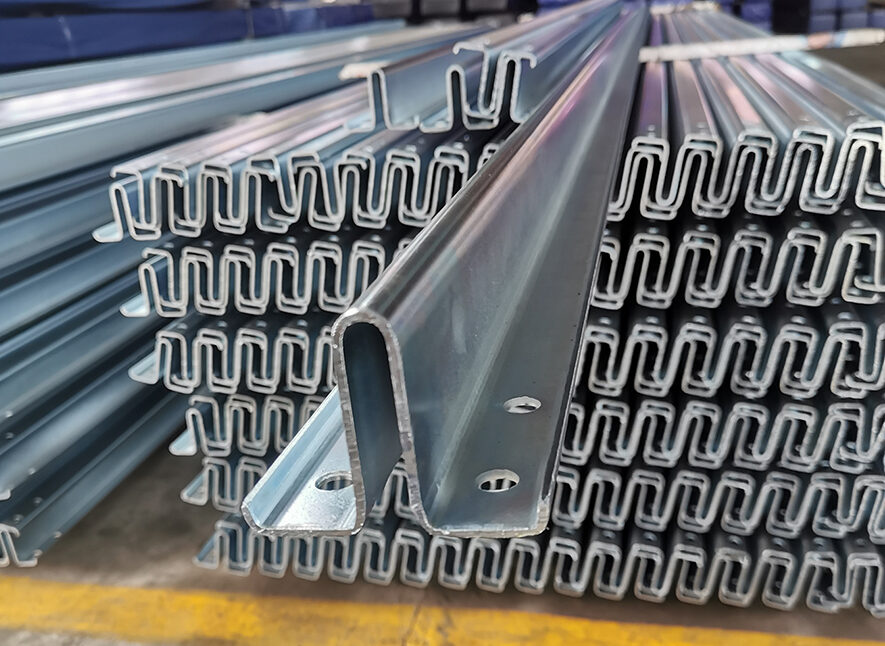

Throughout the history of elevator development in China, it can be seen that elevator technology has developed very rapidly. Applying fuzzy theory, serial communication technology, and microcomputer control technology to replace outdated relay control with contacts; Replace the outdated AC-2 AC dual speed drive with advanced frequency conversion and variable voltage speed regulation; Replace inefficient worm gear transmission with efficient permanent magnet gearless transmission or planetary gear transmission; Replacing traditional old door machines with variable frequency speed control door machines; Replacing traditional mechanical safety touchboards with collision free photoelectric door protection devices; Replacing non-standard angle steel auxiliary guides with hollow auxiliary guides or lightweight T-shaped guides, etc. Technological progress has created favorable external conditions for the renovation of in-service elevators. The application of these new technologies and components requires meticulous redesign by units engaged in renovation to achieve good renovation results.